Custom Made Profile

Custom Made Profile Specification

- Product Type

- Custom Made Profile

- Material

- Aluminium

- Type

- Extruded

- Shape

- As per drawing / requirement

- Technique

- Extrusion

- Surface Treatment

- Anodized, Powder Coated, Mill Finish

- Standard

- ASTM / EN / IS

- Outer Diameter

- Custom as per drawing

- Length

- Up to 6 Meters (Customizable)

- Inside Diameter

- Custom as per requirement

- Wall Thickness

- 0.5 mm up to requested

- Tensile Strength

- 150-250 MPa (Approx)

- Grade

- 6063, 6061, 6005, 6082 or customized

- Size

- As per specification

- Color

- Silver, Black, Customized

- Features

- Lightweight, High Durability, Precision Dimension, Customized Design

- Finish Options

- Matte, Glossy, Textured

- Hardness

- 60-120 HB

- Lead Time

- 730 days depending on order quantity

- Corrosion Resistance

- Excellent

- Packaging

- Standard Export Packaging

- Application

- Construction, Industrial, Architectural, Automotive, Custom Engineering

- MOQ

- As per order

Custom Made Profile Trade Information

- Minimum Order Quantity

- 1000 Dozen

- Payment Terms

- Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Asia, Central America

- Main Domestic Market

- All India

- Certifications

- ISO 9001: 2008

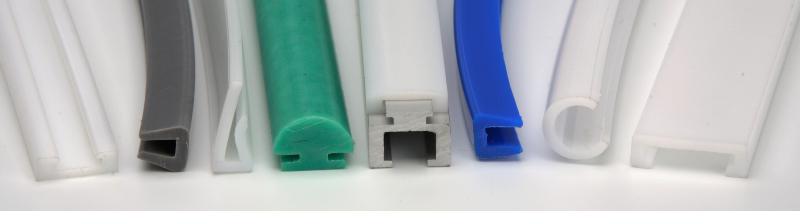

About Custom Made Profile

- Profiles and shapes of various plastics as per your drawing, application or sample

- Standard profiles are T Profiles for furniture, Sealing profile for control panels, U profiles for control panels and electrical applications, L profile of high temperature for CT/VT , Please contact us with your drawing or sample to know if we already have tools for your requirement

- Size can be from 5 mm to 50 mm, in varying thickness, for custom applications.

- Solid and Hollow profiles.

- Commercial and engineering plastics like flexible PVC, Rigid PVC, PP, HDPE, LDPE, LLDPE, PU, ABS, Nylon, Delrin, etc

- Special properties like Fire Retardant (UL94 HB to V0), finish, etc can be made as per your requirement

Versatile Applications Across Industries

Engineered for a variety of uses, this aluminium profile is particularly suitable for construction, industrial manufacturing, architectural projects, automotive components, and specialized engineering tasks. Its adaptability ensures it seamlessly integrates into both standard and unique project demands.

Customization Down to the Last Detail

Clients can specify every aspect, from wall thickness and outer/inner diameters to shape and finish, ensuring the final product precisely meets their functional and aesthetic needs. This level of customization allows for optimal flexibility regardless of project complexity.

Superior Quality and Durability

Utilizing robust aluminium alloys such as 6063, 6061, 6005, or 6082, and advanced extrusion processes, the profile delivers enduring hardness (60120 HB) and tensile strength (150250 MPa). Its surface treatmentsincluding anodized, powder-coated, or mill finishfurther enhance longevity against corrosion and wear.

FAQs of Custom Made Profile:

Q: How is the custom made aluminium profile manufactured to meet specific project requirements?

A: Each profile is produced using precision extrusion techniques based on client-provided drawings and specifications. Sizes, wall thickness, shape, and surface treatments are fully customizable, allowing the final product to be tailored for the intended application.Q: What are the main applications for this corrosion-resistant aluminium profile?

A: This profile is ideal for use in construction, industrial frameworks, architectural elements, automotive parts, and custom engineering solutions due to its combination of strength, lightweight nature, and corrosion resistance.Q: When can I expect delivery after placing an order?

A: Lead times typically range between 7 and 30 days, depending on the order quantity and specific customization requirements. Precise scheduling is confirmed during the order process.Q: Where is the product manufactured and shipped from?

A: The profiles are manufactured in India, adhering to international standards (ASTM, EN, IS), and distributed globally as an exporter, manufacturer, and supplier.Q: What is the process for customizing the profiles dimensions, finish, and color?

A: Clients provide detailed specifications, including required dimensions, finish (matte, glossy, textured), and color (silver, black, or custom). The manufacturing team assesses the feasibility and ensures the final product matches all customized requirements.Q: How does the products corrosion resistance benefit long-term usage?

A: Excellent corrosion resistance, achieved through premium alloys and surface treatments, extends the products lifespaneven in harsh environmentsreducing maintenance and replacement costs over time.Q: What packaging options are available for exported orders?

A: All profiles are securely packed using standard export packaging to ensure they arrive in perfect condition, regardless of shipping destination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC tube Category

PVC Cord Gasket

Price 15 INR / Meter

Minimum Order Quantity : 1000

Grade : Industrial Grade

Surface Treatment : Other, Smooth

Technique : Extruded

Size : Custom sizes available

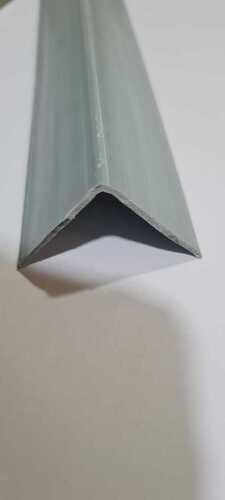

PVC Angle

Price 20 INR / Meter

Minimum Order Quantity : 1000

Grade : Standard

Surface Treatment : Other, Smooth Surface

Technique : Extrusion, Other

Size : Customizable

ABS Profile

Price 10 INR / Meter

Minimum Order Quantity : 1000

Grade : Standard

Surface Treatment : Other, Raw/Untreated

Technique : Other, Extrusion

Size : Varies (Customizable)

Silicone Profile

Price 9 INR / Meter

Minimum Order Quantity : 1000

Grade : Standard

Surface Treatment : Other, Smooth

Technique : Other, Extrusion

Size : Custom