Specification

- प्रॉडक्ट टाइप

- मटेरियल

- टाइप करें

- शेप

- तकनीक

- सतह का उपचार

- स्टैण्डर्ड

- बाहरी व्यास

- 3 mm, 4 mm, 5 mm, 6 mm (Sizes Available)

- लम्बाई

- 1 meter, 2 meter (Custom Lengths Available)

- दीवार की मोटाई

- Solid (No Wall Thickness)

- टेन्साइल स्ट्रेंथ

- >22 MPa

- ग्रेड

- PE100 / PE80

- साइज

- Standard & Custom Sizes

- रंग

- Black, White, Natural

About

We specialize in manufacturer of high qualityHDPE WELDING ROD extruded products since many years, with specialization in the manufacture ofHDPE WELDING RODSize 1mm,2mm,3mm,4mm,5mmVersatile Performance and Reliability

HDPE Welding Rods meet the demanding needs of plastic fabrication, pipe repair, and welding of HDPE sheets and tanks. Their exceptional tensile strength (>22 MPa), high flexibility, and excellent impact resistance make them ideal for both manual and automatic welding processes, ensuring long-lasting, durable joints in diverse environments.

Superior Chemical and Temperature Resistance

These rods are engineered to withstand harsh chemicals such as acids, alkalis, and solvents, making them suitable for industrial and chemical sector applications. HDPEs broad operating temperature range from -40C to +80C allows reliable performance even in extreme climates, while optional UV resistance enhances their suitability for outdoor installations.

FAQs of HDPE Welding Rod:

Q: How are HDPE welding rods used in pipe repair and fabrication?

A: HDPE welding rods are extruded round sticks that are manually or automatically welded to connect or repair HDPE pipes, sheets, and tanks. The rods melt at 130C to 135C, fusing securely with existing HDPE material to build, patch, or reinforce components.Q: What makes HDPE welding rods resistant to chemicals?

A: HDPE welding rods possess a molecular structure that provides resistance to a wide range of acids, alkalis, and solvents, ensuring reliable performance in aggressive chemical environments commonly found in industrial and wastewater applications.Q: When should you choose HDPE welding rods with UV resistance?

A: UV-resistant HDPE welding rods should be used when installations are exposed to sunlight for prolonged periods, such as in outdoor welding of HDPE tanks or pipelines, to prevent material degradation and maintain structural integrity.Q: Where are these welding rods commonly applied?

A: They are widely used in industries for plastic fabrication, pipe repair, welding of HDPE sheets, manufacturing tanks, and similar operations in sectors like chemical processing, water treatment, and packaging.Q: What process is involved in welding with HDPE rods?

A: Welding HDPE rods involves heating the rod and base HDPE material to their melting point (130C135C) using a hot air gun or plastic welder. Once softened, the rod is fused to create a clean, strong joint.Q: What are the benefits of using HDPE welding rods from Indian exporters and manufacturers?

A: Choosing HDPE welding rods from Indian manufacturers ensures compliance with ASTM D3350 and IS standards, solid extrusion quality, customizable sizes, and reliable supply for various industrial needs at competitive pricing.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in पीवीसी ट्यूब Category

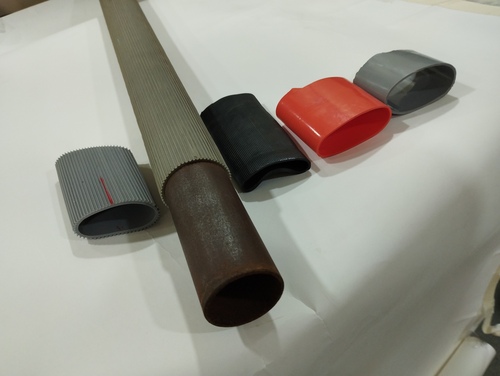

रोलर्स और औद्योगिक कन्वेयर के लिए पीवीसी ट्यूब

मटेरियल : पीवीसी

मूल्य की इकाई : मीटर/मीटर

न्यूनतम आदेश मात्रा : 120

रंग : ग्रे, नारंगी, लाल और काला

माप की इकाई : मीटर/मीटर

प्रॉडक्ट टाइप : अन्य

पेट्रोल पाईप

मटेरियल : पीवीसी

मूल्य की इकाई : मीटर

न्यूनतम आदेश मात्रा : 1000

रंग : सफ़ेद

माप की इकाई : मीटर

हैवी ड्यूटी गार्डन पाइप

मटेरियल : ,

मूल्य की इकाई : मीटर

न्यूनतम आदेश मात्रा : 1000

रंग : Black

माप की इकाई : मीटर

प्रॉडक्ट टाइप : Other