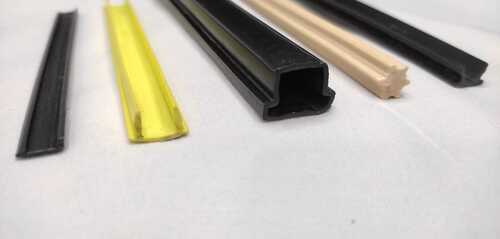

PE Tube for Dozing Pump

26 आईएनआर/Meter

उत्पाद विवरण:

X

मूल्य और मात्रा

- 1000

उत्पाद वर्णन

We specialize in manufacturer of high qualityPE TUBE FOR DOZING PUMPextruded products since many years, with specialization in the manufacture of PE TUBE FOR DOZING PUMPTell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email