Hytrel Tube

Hytrel Tube Specification

- Product Type

- Hytrel Tube

- Material

- Hytrel

- Type

- Flexible Tube

- Shape

- Round

- Technique

- Extruded

- Surface Treatment

- Smooth Finish

- Standard

- ASTM D3159

- Outer Diameter

- 4 mm to 30 mm

- Length

- Rolls (up to 100 m), or custom cut

- Inside Diameter

- 2 mm to 25 mm

- Wall Thickness

- 0.5 mm to 3 mm

- Tensile Strength

- 30-35 MPa

- Grade

- Standard/Custom

- Size

- all type size

- Color

- black white

- Packaging

- Coil, roll, or custom packing available

- Applications

- Automotive, pneumatic, robotics, fluid transfer

- Elongation at Break

- 350% minimum

- Hardness (Shore D)

- 45-72

- Working Temperature

- -40°C to +135°C

- Compliance

- RoHS Compliant

- Resistance

- Excellent chemical, abrasion, and weather resistance

Hytrel Tube Trade Information

- Minimum Order Quantity

- 1000 Meter

- Delivery Time

- 7 Days

About Hytrel Tube

Discover the superb Hytrel Tube: a classic choice favored in automotive, pneumatic, robotics, and fluid transfer applications. With a terrific hardness range (Shore D: 45-72), excellent resistance to chemicals, abrasion, and weather, and favorable reviews from industry experts, this flexible tube offers lasting performance. Its remarkable elongation at break (350% minimum) and tensile strength (30-35 MPa) make it scarce among similar products. Available in black or white, standard or custom sizesall manufactured to ASTM D3159 standards. Last chance to secure top-tier quality from a leading exporter, manufacturer, and supplier in India.

Industrial Performance and Plant Application

Hytrel Tubes are extensively used in manufacturing plants for fluid transfer, pneumatic systems, and robotics integration. Leading automotive companies and industrial manufacturers rely on their consistent durability and smooth finish. Other notable features include broad compatibility with various equipment, custom sizes, and safe working temperatures from -40C to +135C. Enhanced chemical resistance and RoHS compliance make these tubes ideal for demanding plant environments seeking reliability.

Export Markets, Certifications, and Packaging Options

Estimate your requirements for Hytrel Tubes with confidencethese products hold up to ASTM D3159 standards and RoHS compliance. Main export markets include Europe, Asia, and North America, supported by timely offer and dispatch upon purchase order. Packaging details are based on customer preference: coils, rolls (up to 100 meters), or custom cuts. Each order is carefully prepared to guarantee safe delivery and satisfaction, meeting the diverse needs of global clients.

Industrial Performance and Plant Application

Hytrel Tubes are extensively used in manufacturing plants for fluid transfer, pneumatic systems, and robotics integration. Leading automotive companies and industrial manufacturers rely on their consistent durability and smooth finish. Other notable features include broad compatibility with various equipment, custom sizes, and safe working temperatures from -40C to +135C. Enhanced chemical resistance and RoHS compliance make these tubes ideal for demanding plant environments seeking reliability.

Export Markets, Certifications, and Packaging Options

Estimate your requirements for Hytrel Tubes with confidencethese products hold up to ASTM D3159 standards and RoHS compliance. Main export markets include Europe, Asia, and North America, supported by timely offer and dispatch upon purchase order. Packaging details are based on customer preference: coils, rolls (up to 100 meters), or custom cuts. Each order is carefully prepared to guarantee safe delivery and satisfaction, meeting the diverse needs of global clients.

FAQs of Hytrel Tube:

Q: How does the Hytrel Tube perform in harsh environments?

A: The Hytrel Tube provides superb resistance to chemicals, abrasion, and weather, ensuring reliable operation even in harsh industrial, automotive, or robotic settings.Q: What is the process for obtaining custom sizes of Hytrel Tubes?

A: Custom sizes can be requested during your purchase order; the manufacturer offers tailored inside and outer diameters, wall thicknesses, and lengths to meet specific requirements.Q: Where are Hytrel Tubes mainly used?

A: Hytrel Tubes are predominantly used in automotive plants, pneumatic systems, robotics, and fluid transfer applications due to their flexibility, toughness, and excellent resistance properties.Q: When can I expect delivery after placing a purchase order?

A: Delivery timelines are provided with each offer; global export arrangements ensure orders are dispatched promptly according to destination and packaging preferences.Q: What benefits does Hytrel Tube offer compared to traditional tubing materials?

A: Hytrel Tubes stand out with superior elongation at break, higher tensile strength, and broader working temperature ranges, alongside classic durability and compliance to international standards.Q: How can I estimate the quantity required for my facility?

A: You can estimate your requirements based on the application: choose from coils, rolls, or custom cuts, and consult with the supplier for optimal measurements matching your project needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in PVC tube Category

Polysulfone Profile

Price 11 INR / Meter

Minimum Order Quantity : 1000

Product Type : Other, Profile

Material : Polysulfone, Other

Color : Brown

Technique : Other, Extrusion

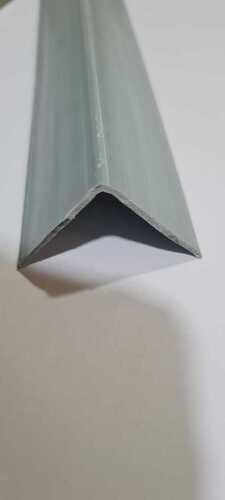

PVC Angle

Price 20 INR / Meter

Minimum Order Quantity : 1000

Product Type : Angle, Other

Material : Pvc

Color : Gray

Technique : Extrusion, Other

Transparent Packaging Tube

Minimum Order Quantity : 2500 Pieces

Product Type : Other

Material : Pvc

Color : transparent , opaque, translucent, etc

Technique : Extruded

Biodegradable Tube

Price 6 INR / Meter

Minimum Order Quantity : 1000

Product Type : Other

Material : Other, Biodegradable polymer

Color : Transparent

Technique : Other, Extrusion