Poly Propylene Profile

Poly Propylene Profile Specification

- Product Type

- Polypropylene Profile

- Material

- Polypropylene (PP)

- Technique

- Extrusion Molding

- Surface Treatment

- Smooth / Matte Finish

- Standard

- IS Standard / ASTM D4101

- Length

- Standard 1-6 Meter (Custom Lengths Available) Meter (m)

- Wall Thickness

- 1 mm - 10 mm Millimeter (mm)

- Tensile Strength

- 25-35 MPa Megapascals (MPa )

- Grade

- Virgin / Reprocessed PP

- Size

- Custom Sizes Available

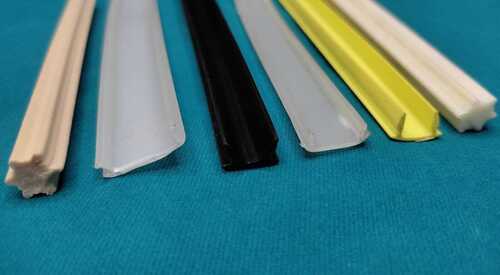

- Color

- Natural, White, Black, Blue, Custom

- Chemical Resistance

- Excellent against acids, alkalis, solvents

- Applications

- Automotive, Construction, Chemical, Packaging, Electrical Industries

- Density

- 0.91 g/cm³

- UV Resistance

- Available with UV stabilized formulation

- Packaging

- Bundled, Shrink-wrapped or as per client requirement

- Heat Distortion Temperature

- 100°C max

- Operating Temperature Range

- -20°C to +90°C

- Flammability

- HB as per UL94

- Flexural Strength

- 40-50 MPa

- Recyclability

- 100% Recyclable

- Water Absorption

- <0.1% after 24 hours

- Compliance

- RoHS and REACH Compliant

Poly Propylene Profile Trade Information

- Minimum Order Quantity

- 1000 Meter

- Sample Available

- Yes

About Poly Propylene Profile

Commercial Applications & Competitive Advantages

Poly Propylene Profile is widely used throughout the automotive, construction, chemical, electrical, and packaging sectors. Its primary competitive advantages include exceptional chemical resistance, an extensive operating temperature range, and complete recyclability. Plant installations benefit from its robust flexural and tensile strengths, while customizable shapes and finishes support various equipment layouts and systems. This profile aligns with industry standards, making it a preferred choice for manufacturers seeking reliability and cost efficiency.

FOB Port, Packaging & Quick Delivery Details

Goods can be shipped from major Indian FOB ports, with packaging tailored to client preferencesbundled, shrink-wrapped, or custom methods. Estimate delivery times are typically prompt, ensuring your project is not delayed. Handover of goods is managed meticulously to secure safe transit. Shipped goods comply with all regulatory standards, and clients have full flexibility in defining packaging and delivery instructions, optimizing convenience and operational planning.

FAQs of Poly Propylene Profile:

Q: How can I customize the size and color of the Poly Propylene Profile?

A: You can specify your required inside or outside diameter, wall thickness, length, and color (natural, white, black, blue, or custom) during the procurement process. Our manufacturing accommodates various custom requests to match your project needs.Q: What applications are best suited for Poly Propylene Profile?

A: This profile is ideal for use in automotive, construction, chemical processing, electrical components, and packaging due to its robust chemical resistance, structural integrity, and adaptability to different environments.Q: When can I expect delivery after placing an order?

A: Delivery timelines are estimated based on your order specifications and location. Standard lead times are quick, with goods typically shipped promptly from major Indian ports. Please reach out for a detailed shipping estimate.Q: Where is the Poly Propylene Profile manufactured and exported from?

A: Poly Propylene Profiles are manufactured in India and exported globally. We maintain high-quality standards as per IS Standard and ASTM D4101, with robust exporter and supplier capabilities.Q: What is the process for procuring Poly Propylene Profiles?

A: Start by submitting your requirements for dimensions, grade, finish, and packaging. Once specifications and order volume are confirmed, the manufacturing and shipping process is initiated, ensuring handover of certified, top-quality profiles.Q: How does UV resistance enhance the profiles performance?

A: The UV-stabilized formulation enables the profile to withstand prolonged sunlight exposure without degradation, making it highly recommended for outdoor and high UV applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC tube Category

HIPS Tube

Price 20 INR / Meter

Minimum Order Quantity : 1000

Product Type : Other, HIPS Tube

Material : Other, High Impact Polystyrene (HIPS)

Color : White, Black, Customized

Shape : Round

PE TUBE FOR ALKALINE PUMP

Price 5 INR / Meter

Minimum Order Quantity : 1000

Product Type : Other, Tube

Material : Other, PE (Polyethylene)

Color : Transparent

Shape : Round

PPO PVC Profile

Price 13 INR / Meter

Minimum Order Quantity : 1000

Product Type : Other, Profile

Material : PPO PVC, Other

Color : Black Olive Green

Shape : Other, Rectangular Hollow

PU PROFILE

Price 4.00 INR / Meter

Minimum Order Quantity : 1000

Product Type : Other

Material : Other, Polyurethane (PU)

Color : Green Transparent White