PET TUBE

PET TUBE Specification

- Product Type

- Other

- Material

- PET (Polyethylene Terephthalate)

- Type

- Tube

- Shape

- Round

- Technique

- Extruded

- Surface Treatment

- Smooth

- Standard

- Industrial/Custom

- Outer Diameter

- 1 to 75 Foot (ft)

- Length

- Custom Length

- Inside Diameter

- Customizable

- Wall Thickness

- 0.5 Feet (ft)

- Tensile Strength

- High

- Grade

- Food, Medical & Industrial

- Size

- As per requirement

- Color

- as per required

- Chemical Resistance

- High

- Temperature Resistance

- Up to 120°C

- Hardness

- 65-85 Shore D

- Recyclability

- 100% Recyclable

- Application

- Packaging, Electrical Insulation, Display, etc.

- Transparency

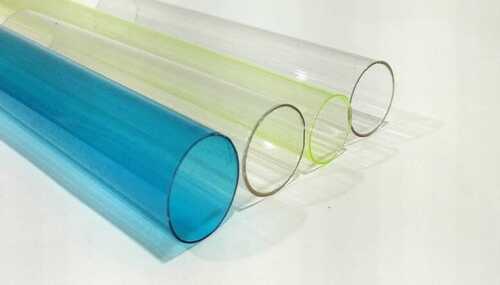

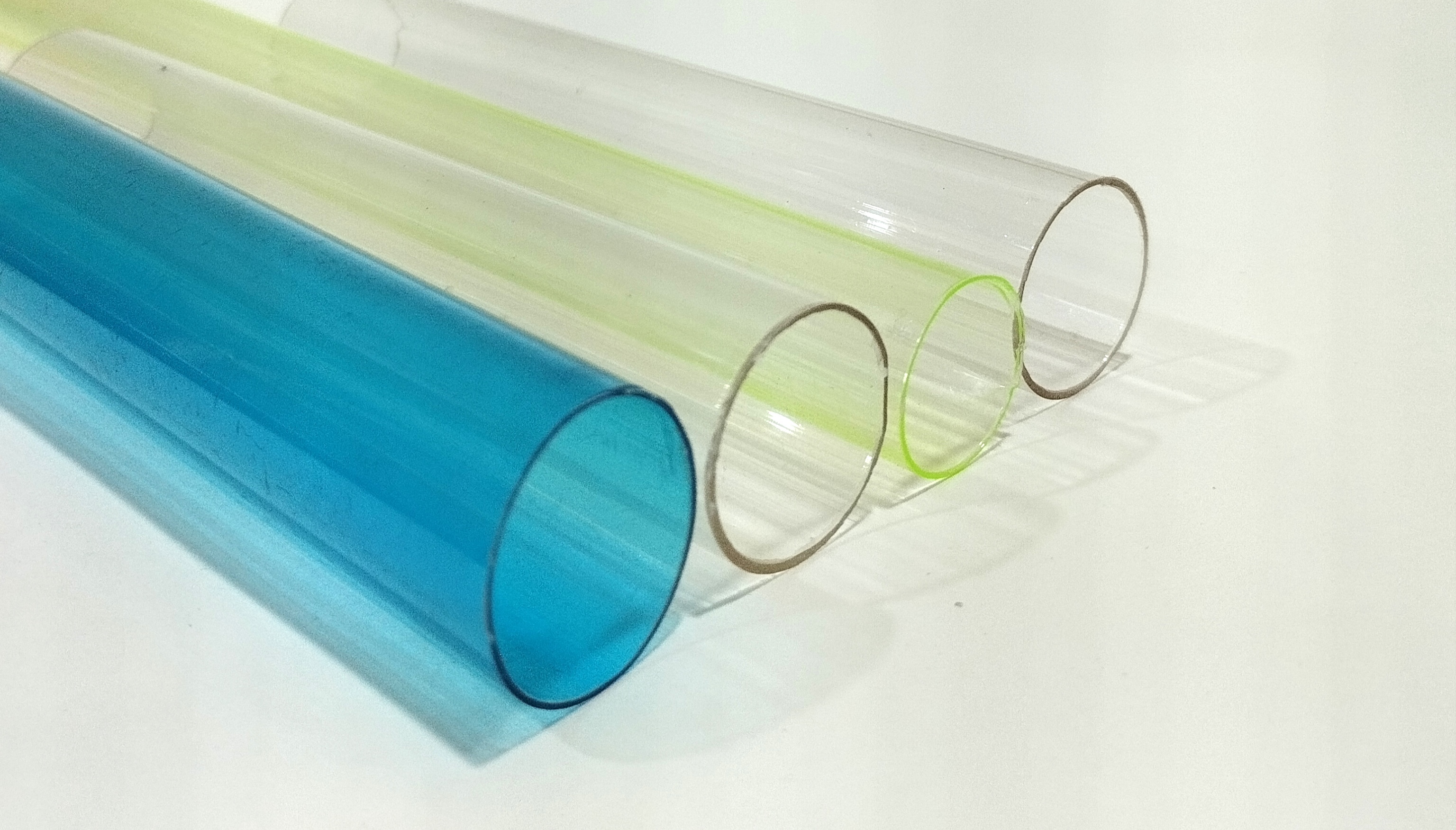

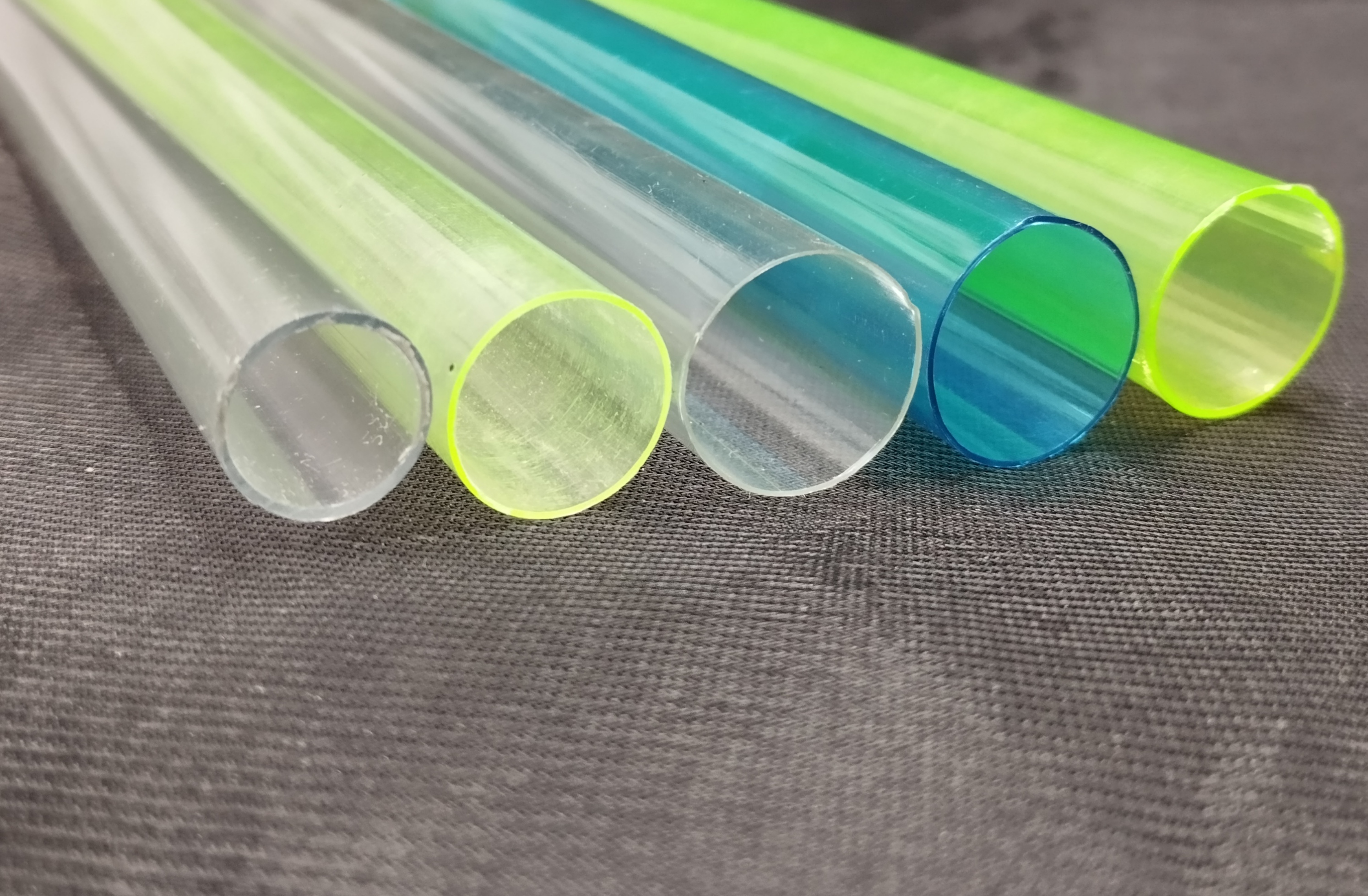

- Clear or Colored

- Flame Retardancy

- Non-Flammable

About PET TUBE

We manufacture transparent packing tube for packing industrial products like drill, bearing,etc We specialize in manufacturer of high quality extruded products since many years, with specialization in the manufacture of PET Tube. We make the size as per your dimensionMultipurpose PET Tube Applications

Engineered with high clarity and robust chemical resistance, the PET Tube is suitable for packaging sensitive items, insulating electrical components, and creating dynamic display solutions. Its customizability in color, diameter, and length make it adaptable for food, medical, and industrial environments alike.

Sustainability and Safety Features

The PET Tube is designed to be 100% recyclable and non-flammable, offering a safe, environmentally conscious option for diverse industries. Its high tensile strength ensures durability, while compliance with stringent standards expands its usability in regulated applications.

FAQs of PET TUBE:

Q: How is the PET Tube customized to suit specific application requirements?

A: The PET Tubes dimensions, wall thickness, color, and length can be tailored according to the clients needs. Both inner and outer diameters are adjustable, and it can be manufactured to precise sizes and shades as per industry or customer specifications.Q: What makes PET Tubes a preferred choice for electrical insulation and packaging?

A: PET Tubes provide high chemical resistance, excellent clarity, and withstand temperatures up to 120C. Their smooth, extruded surface and consistent round shape ensure reliable insulation and secure packaging of sensitive items.Q: When should I consider using PET Tubes over other materials?

A: PET Tubes are ideal when you need material that is transparent, lightweight, food or medical grade, and offers high strength and chemical resistance. They are particularly suitable when flame-retardant and eco-friendly options are a priority.Q: Where can PET Tubes be effectively utilized?

A: These tubes find usage across various environmentsindustrial packaging lines, medical laboratories, food storage, retail displays, and as parts of electrical assemblies due to their adaptability and robust properties.Q: What is the process behind the manufacturing of PET Tubes?

A: PET Tubes are produced using an extrusion technique, where PET material is heated and shaped through precision molds, resulting in smooth, round tubes with consistent wall thickness and customizable features.Q: What are the main benefits of using a PET Tube?

A: Key benefits include high temperature and chemical resistance, strong mechanical properties, non-flammability, full recyclability, and suitability for a range of regulated industries. They also offer aesthetic versatility with clear or colored options.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC tube Category

WELDING MACHINE TUBE

Price 15 INR / Meter

Minimum Order Quantity : 1000

Shape : Round

Material : Other, Highquality PVC/Plastic

Product Type : Other, Welding Machine Tube

Color : Blue,White, Green And Blak

PE TUBE FOR ALKALINE PUMP

Price 5 INR / Meter

Minimum Order Quantity : 1000

Shape : Round

Material : Other, PE (Polyethylene)

Product Type : Other, Tube

Color : Transparent

PU TUBE

Price 7 INR / Meter

Minimum Order Quantity : 1000

Shape : Round

Material : Other

Product Type : Other

Color : Blue, Red, Yellow, Green, Black, Transparent, Other colors on request

Drip Irrigation Tubes

Price 4 INR / Meter

Minimum Order Quantity : 1000

Shape : Round

Material : Other, HDPE

Product Type : Other, Drip Irrigation Tubes

Color : Black