Prototype Development

Prototype Development Specification

- Product Type

- Prototype Development

- Material

- Mild Steel

- Type

- Prototype

- Shape

- Customized

- Technique

- CNC Machining

- Surface Treatment

- Polished

- Standard

- ISO 9001:2015

- Outer Diameter

- As per drawing

- Length

- Custom

- Inside Diameter

- As per requirement

- Wall Thickness

- Custom/As specified

- Tensile Strength

- 370-410 MPa

- Grade

- Industrial

- Size

- Custom

- Color

- Silver

- Tolerance

- +/- 0.01 mm

- Corrosion Resistance

- Yes

- Design Service

- Available on Request

- Application

- Industrial/Engineering

- Finish

- Smooth

- Production Capacity

- 1000 Units/Month

- Precision Level

- High Precision

- Machining Process

- Turning, Milling, Drilling

- Packaging Type

- Safe Industrial Packaging

- Compatibility

- As per client specification

Prototype Development Trade Information

- Payment Terms

- Cash Advance (CA)

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia

- Certifications

- ISO 9001: 2008

About Prototype Development

- We undertake prototype development using low cost injection moulds, assembly of parts, etc to see if the final component will perform as per your design

- If the material, dimensions are not known, we can help design this based on your application.

Precision Engineering Tailored to Your Needs

Our prototypes are engineered with high precision and manufactured to custom specifications for industrial applications. We utilize advanced CNC machining to ensure reliable dimensional accuracy, tight tolerances, and superior finishes.

Quality and Performance Standards

Each prototype is produced from industrial-grade mild steel, with tensile strengths of 370-410 MPa. With ISO 9001:2015 certified processes, clients receive durable, corrosion-resistant components optimized for performance.

Comprehensive Design and Support Services

Our team offers design assistance, material selection, and expert advice to ensure your prototypes meet specific requirements. From initial consultation to final delivery, we focus on flexibility and technical excellence.

FAQs of Prototype Development:

Q: How is a high-precision prototype developed for industrial applications?

A: We employ CNC machining techniques, including turning, milling, and drilling, to fabricate prototypes from mild steel. Our process maintains tight tolerances of +/- 0.01 mm and delivers a polished, corrosion-resistant finish, according to client-specific drawings and requirements.Q: What materials and standards are used for prototype manufacturing?

A: All prototypes are made from industrial-grade mild steel and manufactured under ISO 9001:2015 certified processes. This ensures the component meets stringent industry and quality standards, including high strength and corrosion resistance.Q: When can I expect delivery of prototypes and what is the production capacity?

A: Our typical production capacity is up to 1000 units per month. Lead times vary based on the complexity and volume of your order, but we prioritize efficiency and timely delivery for every project.Q: Where are your prototype development services available from?

A: We are an exporter, manufacturer, and supplier based in India, serving global clients. Safe industrial packaging and logistics ensure your prototypes arrive secure and ready for application.Q: What is the process for customizing the design and finish of prototypes?

A: Clients can provide specific drawings or requirements for size, shape, diameter, and surface finish. Our team collaborates with you during the design phase and offers custom machining and surface treatments as needed.Q: How are the prototypes intended to be used in industrial or engineering applications?

A: Our high-precision prototypes are suitable for various industrial and engineering uses, such as functional testing, validation, or as pre-production models to evaluate fit, form, and performance before mass manufacturing.Q: What are the main benefits of choosing your prototype development service?

A: Clients benefit from meticulous quality control, high dimensional accuracy, versatile customization options, corrosion resistance, and the support of an experienced design teamensuring optimal results for complex engineering projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC tube Category

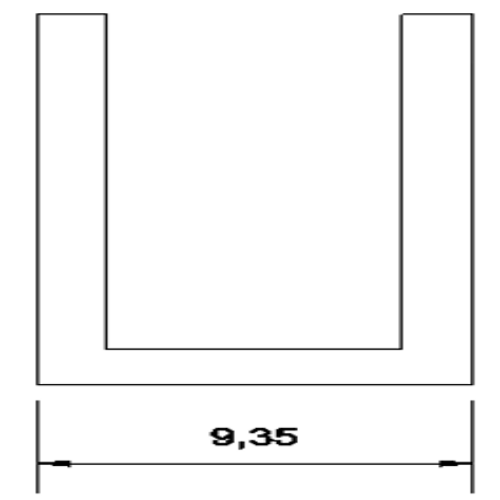

U Profile For Furniture

Price 40 INR / Meter

Minimum Order Quantity : 1000

Color : Silver

Grade : 6063 T5

Material : Other, Aluminium

Standard : Other, ASTM/BIS

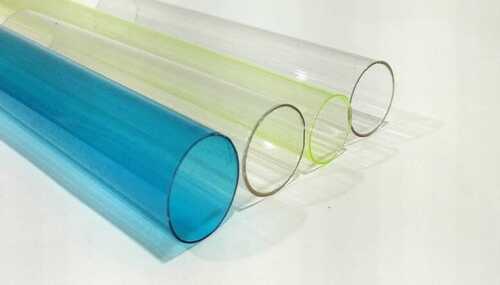

PET TUBE

Price 20 INR / Meter

Minimum Order Quantity : 1000

Color : as per required

Grade : Food, Medical & Industrial

Material : Other, PET (Polyethylene Terephthalate)

Standard : Other, Industrial/Custom

TPE TUBE

Price 9 INR / Meter

Minimum Order Quantity : 1000

Color : Black

Grade : Standard

Material : Other, TPE (Thermoplastic Elastomer)

Standard : Other, Standard

Silicone Profile

Price 9 INR / Meter

Minimum Order Quantity : 1000

Color : White

Grade : Standard

Material : Other, Silicone

Standard : Other, Industry Standard